Home / Products / Spindle Bearings

Precision Angular Contact Ball Bearings

718 Series

Inner Diameter: 100-850mm

Outer Diametr: 128-1030mm

Width: 13-82mm

Weight: 0.2-140kg

719 Series

Inner Diameter: 100-750mm

Outer Diametr: 140-950mm

Width: 20-106mm

Weight: 0.8-195kg

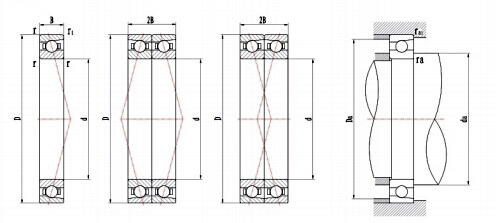

There are two series (718 series and 719 series) of CHG light precision angular contact ball bearings; they have the same inside diameter and the outside diameter and width are increased successively.

The single-row angular contact ball bearing can bear a radial load and an axial load in one direction, and it can bear a single axial load in one direction; under the radial load, its axial component load will be caused. Therefore, the single row angular contact ball bearing should be matched with the other bearing to bear the axial load in the opposite direction. So, 2, 3, 4 or even 5 angular contact ball bearings are usually matched together for use, and the angular contact ball bearing has a high limiting speeds.

The contact angles of CHG light series precision angular contact ball bearings are 15° (Code C), 25° (Code AC) and 40° (Code B); for the angular contact ball bearings, the contact angle is greater, the axial load capacity is larger, but the bearing limiting speeds is lower. Therefore, the bearing with the contact angle of 15° is used on the shaft with high speeds and small axial load; on the contrary, the angular contact ball bearings with the contact angle of 25° or 40° should be used.

CHG precision angular contact ball bearings can be divided into 3 series of high-speed angular contact bearings (standard series), ultra high-speed angular contact ceramic ball bearings, and high speed sealed angular contact ball bearings.

For the roller bearings used under common conditions, the inner and outer rings and rolling elements should be made of high carbon chromium bearing steel; but in some applications, such as in ultra-high speed, wear resistance, low temperature rise, long life and high reliability and other places, the steel bearing performances can not meet the requirements of the use conditions, they should be made of bearing material with more excellent performances, among which, the silicon nitride ceramic is considered as the best alternative for roller bearing steel material.

CHG can also offer angular contact hybrid ceramic ball bearings with wide applications for high-speed precision machine tool spindle and other high-speed precision machinery spindle, in which, the inner and outer rings should be made of high quality bearing steel material, and the rolling elements should be made of silicon nitride ceramics.

Compared with standard steel angular contact ball bearings with the same structure and size, the angular contact hybrid ceramic ball bearings have excellent high-speed performances, high rigidity, low friction heat, long life and other advantages.

CHG precision hybrid ceramic ball bearings (Code HQ1) can significantly increase the spindle speeds, rigidity, reliability and productivity, and dramatically reduce the friction heat of the spindle and extend the host life.

718 Series

Inner Diameter: 100-850mm

Outer Diametr: 128-1030mm

Width: 13-82mm

Weight: 0.2-140kg

719 Series

Inner Diameter: 100-750mm

Outer Diametr: 140-950mm

Width: 20-106mm

Weight: 0.8-195kg

Dimensions | Basic Load Rating | Designation | Weight | Installation Size | Limiting Speed | |||||||||

mm | kN | kg | mm | r/min | ||||||||||

d | D | B | Tmin | hmin | Cr | Cor | da | Da | Ta | ra1 | Grease | Oil | ||

100 | 128 | 13 | 1 | 0.3 | 21.2 | 27.5 | 71820 | 0.2 | 104.6 | 120.4 | 1 | 1 | 8500 | 13000 |

110 | 140 | 16 | 1 | 0.3 | 31.9 | 40.5 | 71822 | 0.51 | 114.6 | 135.4 | 1 | 1 | 8000 | 13000 |

120 | 150 | 16 | 1 | 0.3 | 33.2 | 45 | 71824 | 0.55 | 124.8 | 145.4 | 1 | 1 | 7500 | 12000 |

130 | 165 | 18 | 1.1 | 0.6 | 39 | 53 | 71826 | 0.7 | 136 | 159 | 1 | 7000 | 11000 | |

140 | 175 | 18 | 1.1 | 0.6 | 44.9 | 62 | 71828 | 0.8 | 146 | 169 | 1 | 1 | 6300 | 10000 |

150 | 190 | 20 | 1.1 | 0.6 | 53.5 | 74.5 | 71830 | 1.32 | 156 | 184 | 1 | 1 | 6300 | 9500 |

160 | 200 | 20 | 1.1 | 0.6 | 54 | 78 | 71832 | 1.25 | 166 | 194 | 1 | 1 | 5600 | 8500 |

170 | 215 | 22 | 1.1 | 0.6 | 80 | 110 | 71834 | 2 | 175 | 210 | 1 | 1 | 5600 | 8500 |

Dimensions | Basic Load Rating | Designation | Weight | Installation Size | Limiting Speed | |||||||||

mm | kN | kg | mm | r/min | ||||||||||

d | D | B | Tmin | hmln | Cr | Cor | da | Da | Ta | ral | Grease | Oil | ||

200 | 250 | 24 | 1.5 | 1 | 90 | 130 | 71840 | 2.5 | 208.5 | 241.5 | 1.5 | 1 | 4300 | 6000 |

220 | 270 | 24 | 1.5 | 1 | 151 | 263 | 71844 | 2.5 | 228.5 | 261.5 | 1.5 | 1 | 3800 | 5600 |

240 | 300 | 28 | 2 | 1 | 128 | 175 | 71848 | 4.1 | 250 | 290 | 2 | 1 | 3200 | 4800 |

260 | 320 | 28 | 2 | 1 | 127 | 190 | 71852 | 4.85 | 270 | 310 | 2 | 1 | 1400 | 1900 |

280 | 350 | 33 | 2 | 1 | 140 | 216 | 71856 | 7.2 | 290 | 340 | 2 | 1 | 1200 | 1700 |

320 | 400 | 38 | 2.1 | 1.1 | 190 | 290 | 71864 | 10 | 332 | 388 | 2 | 1 | 800 | 1000 |

340 | 440 | 38 | 2.1 | 1.1 | 219 | 345 | 71872 | 11.1 | 372 | 428 | 2 | 1 | ||

360 | 480 | 46 | 2.1 | 1.1 | 261.9 | 450 | 71876 | 18 | 392 | 468 | 2 | 1 | 1700 | 2400 |

380 | 500 | 46 | 2.1 | 1.1 | 292 | 501 | 71880 | 19.5 | 412 | 488 | 2 | 1 | ||

Dimensions | Basic Load Rating | Designation | Weight | Installation Size | Limiting Speed | |||||||||

mm | kN | kg | mm | r/min | ||||||||||

d | D | B | Tmin | hmin | Cr | Cor | da | Da | Ta | Ta1 | Grease | Oil | ||

420 | 520 | 46 | 2.1 | 1.1 | 294 | 513 | 71884 | 20.4 | 432 | 508 | 2 | 1 | 750 | 1000 |

440 | 540 | 46 | 2.1 | 1.1 | 301 | 540 | 71888 | 21.1 | 452 | 528 | 2 | 1 | 750 | 1000 |

460 | 580 | 56 | 3 | 3 | 334 | 689 | 71892 | 34.5 | 474 | 566 | 2.5 | 1 | 850 | 1000 |

480 | 600 | 56 | 3 | 1.1 | 415 | 820 | 71896 | 35.5 | 494 | 686 | 2.5 | 1 | 850 | 1200 |

500 | 620 | 56 | 3 | 1.1 | 351 | 765 | 718/500 | 38 | 514 | 606 | 2.5 | 1 | 670 | 900 |

530 | 650 | 56 | 3 | 1.1 | 369 | 837 | 718/530 | 39.5 | 544 | 636 | 2.5 | 1 | 1100 | 1600 |

560 | 680 | 56 | 3 | 1.1 | 341 | 837 | 718/560 | 41.5 | 574 | 666 | 2.5 | 1 | 600 | 800 |

600 | 730 | 60 | 3 | 1.1 | 421 | 1044 | 718/600 | 47 | 614 | 766 | 2.5 | 1 | 560 | 750 |

630 | 780 | 69 | 4 | 1.5 | 518 | 1160 | 718/630 | 69.7 | 648 | 715 | 3.1 | 1.5 | ||

670 | 820 | 69 | 4 | 1.5 | 498 | 1161 | 718/670 | 77 | 688 | 802 | 3 | 1.5 | 850 | 1200 |

710 | 870 | 74 | 4 | 1.5 | 546 | 1467 | 718/710 | 93.5 | 725 | 855 | 3 | 1 | 800 | 1100 |

750 | 920 | 78 | 5 | 2 | 585 | 1620 | 718/750 | 110 | 768 | 902 | 4 | 2 | 400 | 530 |

850 | 1030 | 82 | 5 | 2 | 620 | 1674 | 718/850 | 140 | 868 | 1012 | 4 | 2 | 340 | 450 |

Note:

1.Rate and speed in the catalogue is changed with the change of contact angle ,please consult technical department.

2.Our company can also produce diameter series 7 bearings(Super thin-section),please consult technical department.

Dimensions | Basic Load Rating | Designation | Weight | Installation Size | Limiting Speed | |||||||||

mm | kN | kg | mm | r/min | ||||||||||

d | D | B | Tmin | hmin | Cr | Cor | da | Da | Ta | ra1 | Grease | Oil | ||

100 | 140 | 20 | 1.1 | 0.6 | 60.6 | 65.5 | 71920 | 0.8 | 106 | 134 | 1 | 1 | 8500 | 14000 |

110 | 150 | 20 | 1.1 | 0.6 | 62.4 | 72 | 71922 | 0.86 | 116 | 144 | 1 | 1 | 8000 | 13000 |

120 | 150 | 20 | 1.1 | 0.6 | 24.7 | 25.5 | 71924 | 1.15 | 116 | 144 | 1 | 1 | 10000 | 15000 |

130 | 180 | 24 | 1.5 | 0.6 | 92.3 | 108 | 71926 | 1.55 | 137 | 173 | 1.5 | 1.5 | 7000 | 11000 |

140 | 190 | 24 | 1.5 | 0.6 | 95.6 | 116 | 71928 | 1.65 | 147 | 183 | 1.5 | 1.5 | 6700 | 10000 |

150 | 210 | 28 | 2 | 1 | 90 | 120 | 71930 | 3 | 160 | 200 | 2 | 1 | 6300 | 9500 |

160 | 220 | 28 | 2 | 1 | 109 | 129 | 71932 | 3 | 170 | 210 | 2 | 1 | 6000 | 9000 |

170 | 230 | 28 | 2 | 1 | 110 | 140 | 71934 | 3.3 | 179 | 221 | 2 | 2 | 5600 | 8500 |

190 | 260 | 33 | 2 | 1 | 139 | 177 | 71938 | 4.45 | 199 | 255 | 2 | 2 | 5000 | 7500 |

Dimensions | Basic Load Rating | Designation | Weight | Installation Size | Limiting Speed | |||||||||

mm | kN | kg | mm | r/min | ||||||||||

d | D | B | Tmin | hmln | Cr | Cor | da | Da | Ta | ral | Grease | Oil | ||

200 | 280 | 38 | 2.1 | 1.1 | 150 | 210 | 71940 | 7.1 | 212 | 268 | 2 | 1 | 4300 | 6000 |

220 | 300 | 38 | 2.1 | 1.1 | 200 | 250 | 71944 | 7.2 | 232 | 288 | 2 | 1 | 3800 | 5600 |

240 | 320 | 38 | 2.1 | 1.1 | 203 | 285 | 71948 | 8.37 | 252 | 308 | 2 | 1 | 3200 | 4800 |

260 | 360 | 46 | 2.1 | 1.1 | 242 | 345 | 71952 | 13.5 | 272 | 348 | 2 | 1 | 1300 | 1800 |

280 | 380 | 46 | 2.1 | 1.1 | 226 | 337 | 71956 | 15 | 292 | 368 | 2 | 1 | 1100 | 1600 |

320 | 440 | 56 | 3 | 1.1 | 350 | 550 | 71964 | 25.5 | 334 | 426 | 2.5 | 1 | 800 | 1000 |

340 | 460 | 56 | 3 | 1.1 | 292 | 510 | 71968 | 27.5 | 354 | 446 | 2.5 | 1 | 800 | 1000 |

360 | 480 | 56 | 3 | 1.1 | 350 | 600 | 71972 | 29 | 800 | 1000 | ||||

380 | 520 | 65 | 4 | 1.5 | 369 | 661.5 | 71976 | 40.5 | 395 | 505 | 3 | 1 | 850 | 1200 |

400 | 540 | 65 | 4 | 1.5 | 380.7 | 702 | 71980 | 42 | 415 | 525 | 3 | 1 | 800 | 1100 |

Dimensions | Basic Load Rating | Designation | Weight | Installation Size | Limiting Speed | |||||||||

mm | kN | kg | mm | r/min | ||||||||||

d | D | B | Tmin | hmin | Cr | Cor | da | Da | Ta | Ta1 | Grease | Oil | ||

420 | 560 | 65 | 4 | 1.5 | 327 | 603 | 71984 | 44.5 | 435 | 545 | 3 | 1 | 700 | 950 |

440 | 600 | 74 | 4 | 3 | 456.3 | 936 | 71988 | 61 | 455 | 585 | 3 | 1 | 750 | 1000 |

460 | 620 | 74 | 4 | 1.5 | 456 | 936 | 71992 | 58 | 475 | 605 | 3 | 1 | 750 | 900 |

530 | 670 | 78 | 5 | 2 | 498 | 1098 | 719/530 | 78 | 518 | 652 | 4 | 1 | 630 | 850 |

560 | 710 | 82 | 5 | 2 | 556 | 1206 | 719/560 | 92 | 558 | 692 | 4 | 1 | 1000 | 1500 |

600 | 750 | 85 | 5 | 2 | 533 | 1161 | 719/600 | 105 | 578 | 732 | 4 | 2 | 560 | 750 |

630 | 800 | 90 | 5 | 2 | 644 | 1557 | 719/630 | 125 | 618 | 782 | 4 | 2 | 900 | 1300 |

750 | 950 | 106 | 6 | 3 | 767 | 1980 | 719/750 | 195 | 733 | 927 | 5 | 2 | 800 | 1100 |

Note:

1.Rate and speed in the catalogue is changed with the change of contact angle,please consult technical department.

2.Our company can also produce diameter series 7 bearings(Super thin-section),please consult technical department.