Home / Products

Read More

Read MoreThin-Section Bearings

The thin section bearings we produce consist of seven series of open types and five series of sealed types. The bore diameter ranges from 1 inch to 40 inch, Cross section ranges from 0.1875 × 0.1875 inch to 1.000 × 1.000 inch. Three kinds open type thin section bearings are available: Radial contact (type C), Angular contact (type A) and Four-point contact (type X). Two kinds sealed thin section bearings are available: Radial contact (type C), and Four-point contact (type X).

Thin section bearings are designed to save space, decrease the overall weight, dramatically reduce friction, and provide excellent running accuracy. The special features of the thin section bearings enable customers to downsize their design and cut manufacturing costs without sacrificing bearing performance or life. Read More

Read MoreCylindrical Roller Bearings

Cylindrical roller bearings are available in a variety of designs, series and sizes. Products including single row bearings with cage, high load bearing, double row bearings, multi-row bearings, single, double and multi-row full complement cylindrical roller bearings (without cage) and split bearings and other standard products. CHG also offers OEM, customized and technical support services.

Cylindrical roller bearings according to the accuracy level can be divided P0, P6, P5, P4, P2. Product series includes:

Single row cylindrical roller bearings, NU seires , N series , NJ series and NUP type

High load cylindrical roller bearings, NCF series , NJF series and NUH type

Double row cylindrical roller bearings, NNU series, NN series and NNUP type

Four row cylindrical roller bearings FC, FCD type, FCDP Type

Single row full complement cylindrical roller bearings, NCF and NJG type

Double row full complement cylindrical roller bearings, NNCL, NNCF, NNC and NNF type

Multi-row full complement c Read More

Read MoreTapered Roller Bearings

The taper roller bearing is a separable type bearing which inner components (consists of rollers, cage, and inner ring) can be separated from outer ring. Therefore, it can be very easily installed onto the journal and bearing housing.

Tapered roller bearings are commonly used for moderate speed, heavy duty applications where durability is required such as machine tool spindles, rolling mills, mining equipment, metallurgy industry, plastics makeing machinery and other industries.

We are a leading manufacturer of quality ball, cylindrical and tapered roller bearings. We offer a variety of configurations to tapered roller bearings such as single-row, double-row and four-row with more than 150 different models in both inch and metric sizes. Tapered roller bearings are made of high carbon chrome steel with many in-stock and ready to ship. Any requirement please contact [email protected] for free price. Read More

Read MoreSlewing Bearings

Slewing bearings are large size bearings which can carry higher axial, radial loads and overturning moments at the same time. Slewing bearings generally have mounting holes, internal or external gears, lubricant holes and sealing equipment.

There are various structures of slewing ring bearings, such as four point contact ball slewing bearing, double row angular contact ball slewing bearings, crossed cylindrical roller slewing bearings, crossed tapered roller bearings and three row cylindrical roller slewing bearings, with gears or no gears.

Four point contact ball slewing bearings possess high static loading capacity; crossed cylindrical roller slewing bearings can carry high dynamic loads; crossed tapered roller slewing bearings have high stiffness and rotation accuracy by preloading.

Slewing ring bearings are widely used in cranes, excavation machines, construction machinery, port cargo handling machinery, large turnplates of high precision radars and missile launchers, etc. Read More

Read MoreBall Bearings

The deep groove ball bearing is the most widely used roller bearing. It’s structure is simple and is easy of use. It is mainly used to bear the radial load. By means of increasing the rib height coefficient, the radial play, etc., the deep-groove ball bearing may have a certain performance of the angular contact ball bearing, i.e. bearing a certain radial load. Compared with other kinds of bearings of the same size, the deep groove ball bearing features lower friction coefficient and high speed limit, but it has low impact resistance and is not applicable to bearing heavy load.

Read More

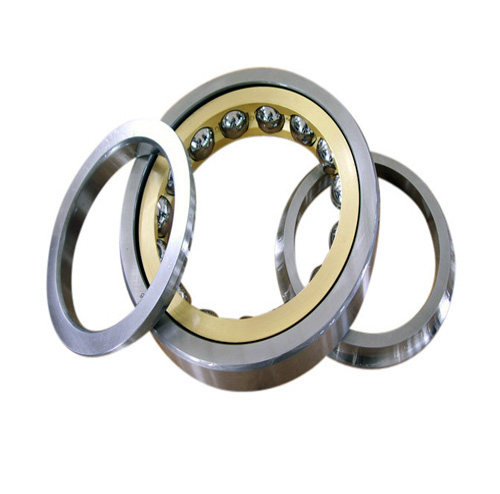

Read MorePrecision Angular Contact Ball Bearing

We are a leading high precision angular contact ball bearing manufacturer and supplier from china, can provide high precision bearing, super precision bearing with different sizes series. CHG precision angular contact ball bearings are widely used in precision CNC machine tools, mechanical spindles, high-speed wire metallurgy equipment, high-speed high-precision mechanical equipment, high temperature and corrosion resistant mechanical equipment, aerospace and other fields; products have been exported to Europe, America and other countries.

Read More

Read MoreCrossed Cylindrical Roller Bearings

Crossed cylindrical roller bearing is one kind of bearing whose rollers are square crossing arranged between outer ring and inner ring. The rollers contact the raceway in linearity, so this bearing has better rigidity and less elastic strain. At the same time, this bearing can carry radial load, axial load and moment load simultaneously. They are especially suitable for high rigidity and high running accuracy applications.

The dimension of the inner and outer rings is a minimum to miniaturization, especially extremely thin type is close to the limit of small size, and high rigidity, so it is optimal for applications such as joints and swiveling units of industrial robots, swiveling tables of machining centers, rotary units of manipulators, precision rotary tables, medical instrument, measuring instruments, IC manufacturing machines, and etc.. Read More

Read MoreCrossed Tapered Roller Bearings

Crossed tapered roller bearing contains double sets of raceways and rollers which are brought together at right angle with alternate rollers facing in opposite directions. Unlike crossed roller bearing, the rolling elements of Crossed tapered roller bearing are tapered rollers. The height of cross section is similar to single-row bearing, thus the design of bearing housing is simplified. The steep-angle tapered geometry makes the effective span of the bearing much greater than the width of the bearing itself. Crossed tapered roller bearings can carry high overturning moment, thus they are widely used in large hobbling machine, industrial robot, high speed vertical lathe, high precision working table, vertical boring machine, and spindle of grinding machine etc.

Read More

Read MoreSpindle Bearings

The Spindle bearings produced by Us can be divided into 4 series: 618 series、619 series、718 series、719 series. With the inner diameter range from 100mm to 950mm, and the precision is divided into P6, P5, P4 and P2. The bearings are available in open and sealed versions.

Spindle bearings have restricted tolerances. They are particularly suitable for bearing with very high requirements for guidance accuracy and speed capacity. They have proved highly suitable for the bearing of spindles in machine tools. Read More

Read MoreThrust Roller Bearings

Generally, the cylindrical roller thrust bearing has one or two rows of rollers, and can bear a considerable axial force as well as a certain vibration load. The structure does not have the radial locating function and cannot bear any radial force, and in addition, it has no self-aligning function.

Read More

Read MoreThrust Ball Bearings

The thrust ball bearings are classified into two kinds: unidirectional thrust bearing and bidirectional thrust bearing. The former can bear the axial force in one direction and the latter can bear he axial forces in two directions. Both unidirectional and bidirectional thrust ball bearings cannot bear any radial force. Thrust ball bearing can limit axial displacement of shafts or housings in one or two direction, but not radial displacement. Therefore, the bearings are usally used with deep groove ball bearings.

Single direction thrust ball bearing consist of one row of balls ( with cage ), a shaft washer ( close fit with shaft ) and a housing ring ( loose fit with shaft and close fit with bore of bearing block ). They can not carry radial loads but axial loads in one direction, because the axial loads are well distributed on each bal, the loading capacity is higher, but the temperatue is high while working, and their limiting speed is lower.

Double direction angular contact thrust b Read More

Read MoreSpherical Roller Bearings

Spherical roller bearings are self-aligning roller bearings. They are double row, self-retaining units comprising solid outer rings with a concave raceway, inner rings with a cylindrical or tapered bore and ball and cage assemblies. Therefore, the bearings are self-aligning and insensitive to misalignment of the shaft relative to the housing, which can be caused, for example, by shaft deflection. The allowable aligning angle ranges from 1°to 2.5°. It is especially suitable for scenarios where the rotating shaft has the possibility of inclination or flexible deformation. We Self-aligning roller bearings are designed to accommodate heavy radial loads, as well as heavy axial loads in both directions.

Read More

Read MoreSpiral Roller Bearing

Features of spiral roller bearings:

Impact—Impact vibration load generated during drawing;

Dust-metal oxides produced during slab cooling;

Sewage-water flow and hot steam from cooling water.

Spiral ring roller bearings mainly include A90000 series and S000 series, which are suitable for high temperature working areas. When the bearing's own temperature reaches 250 ° C, this type of roller bearing can still effectively bear the impact vibration load, ensuring the equipment's operating accuracy Need to be made into an elastomer. Can save a lot of space occupied by the bearing, and is easy to assemble and disassemble.